The Group has set a long-term goal of net-zero greenhouse gas emissions by 2050 in order to contribute to the realization of a decarbonized society. To achieve this goal, we are conducting carbon management including energy conservation and visualization of energy consumption. Going forward, we plan to utilize renewable energy. In April 2022, we also endorsed the recommendations of the Task Force on Climate-related Financial Disclosures(TCFD) and joined the TCFD Consortium. We will analyze and consider our initiatives to promote information disclosure following the TCFD recommendations. For more information, please refer to "Initiatives in Response to the TCFD Recommendations" which is linked below.

Goal of net-zero GHG emissions*1

*1Group consolidated basis.

30% reduction in CO2 emissions*2

*2Scope 1 + 2 (domestic Group consolidated, compared to FY2019/3)

| Target | Results for FY2023 | |

|---|---|---|

| FY2031/3 | -30% | ▲6% |

*Scope 1 + 2 (domestic Group consolidated basis; compared to FY2019/3).

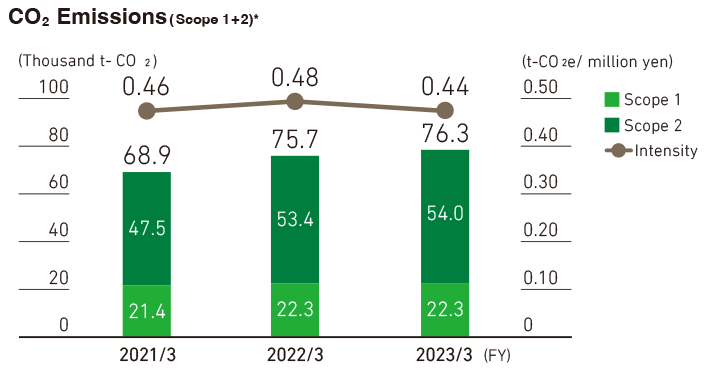

In FY2023, our CO2 emissions decreased by 6% compared with FY2018 and by 9% compared with FY2022 thanks to energy conservation activities and the introduction of renewable energy.

At Takasaki Morinaga Co., Ltd., we started receiving electricity generated from an on-site PPA* solar power generation system in February 2024.

In addition, at the Tsurumi Site, where our R&D Center and factory are located, and at the new Head Office building, where we relocated in March 2024, we have started to introduce the Renewable Energy-Based Electricity Plan. Under this plan, we will source electricity derived from renewable energy sources with zero CO2 emissions for all electricity used.

We will continue to work toward a decarbonized society from various angles.

*On-site PPA: A system in which a power generation company (a PPA operator) installs solar power generation equipment on the premises of a user (e.g., a company) at the expense of the power generation company, owns and maintains it, and supplies the electricity generated from the power generation facility to the user.

| Initiatives | Detail |

|---|---|

| Reducing CO2 emissions at factories |

|

| Initiatives at facilities using fluorocarbons |

|

| Initiatives in logistics |

|

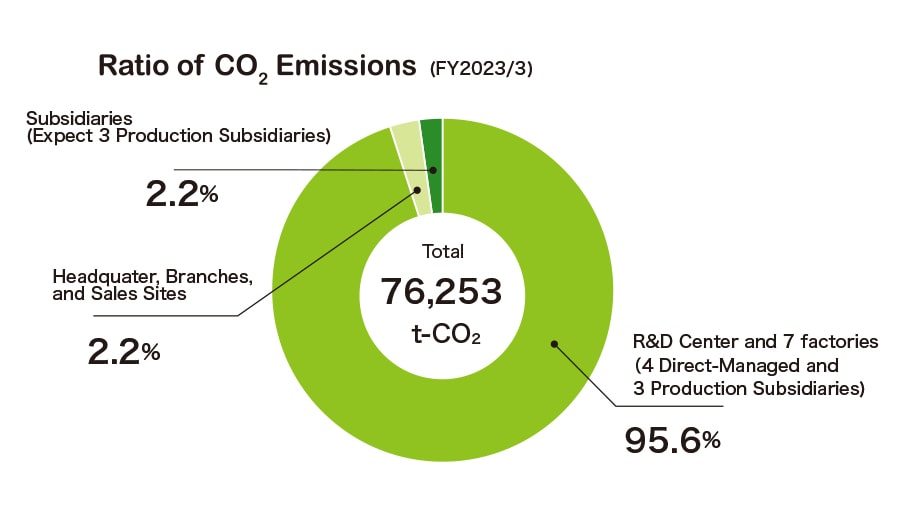

We are working on reducing emissions by measuring the overall volume of current CO2 emissions and making emissions visible.

Because Morinaga's four factories and three affiliated production companies account for a large portion of our CO2 emissions, we are stepping up efforts chiefly in our production division.

*Domestic Group consolidated basis. CO2 emissions are rounded up to the second decimal place. The domestic Group consolidated figure for FY2021/3 and later is third-party assured by LRQA Limited. The Company applied the “Accounting Standard for Revenue Recognition (ASBJ Statement No. 29, March 31, 2020)”, etc., from the beginning of FY2022/3. The figures for FY2021/3 are from after retroactive application of the said accounting standard.

We are currently examining the possibility of replacing CFC-using facilities with those using HCFCs and HFCs, with a low ozone depletion potential, or natural refrigerants. We are replacing equipment and devices that use CFC R-22 with those using a low-global-warming-potential refrigerant. We have also implemented stricter measures to prevent leakage of CFC gas from existing facilities.

Takasaki Morinaga Co., Ltd., Morinaga Angel Dessert Co., Ltd. and Morinaga Dessert Co., Ltd., whose product lines include frozen desserts, use refrigerant-equipments in their large-sized refrigerators with natural refrigerants that has zero ozone-depletion potential and low climate-change coefficient.

We will continue to work on reducing GHG emissions.

In an effort to load as many products as possible on a pallet, a platform used for product storage and transportation, we have adjusted dimensions of cardboard cases and apply our efficient stacking pattern for loading cases onto the pallets. Furthermore, we save the use of energy in the storage and transportation processes by designing our products to minimize the wasted space.

With a view to increasing the productivity of our core brands and responding to diversifying market needs, the Morinaga Group is reorganizing its production systems to make them highly efficient. In FY2020/3, in order to improve productivity, the decision was made to merge Morinaga Snack Foods Co., Ltd. and Morinaga Kofu Foods Co., Ltd. into the Company. The two production bases were closed, while their production lines were partially transferred to the Tsurumi Factory and the Oyama Factory and rebuilt there.

We also built a third factory on the premises of Takasaki Morinaga Co., Ltd., and started production of chocolates in FY2021/3 and frozen desserts in FY2022/3.

In the new factory and relocated production lines, we made capital investments taking into consideration energy saving. For example, we installed highly efficient energy-saving equipment and adopted a building design that features ceilings set lower than those of former buildings for the reduction of air conditioning loads.

Takasaki Factory No.3

In order to make as much contributions as possible to the prevention of global warming, an international environmental issue, we are focusing on the facilitation of energy conservation promotion activities at our production sites, as most of our energy consumption is attributable to these facilities.

We have so far implemented such measures as: conducting energy-saving patrols to prevent overlooking of compressed-air or steam leakage from pipes and failures to switch off the lights; replacement of aged equipment with highly efficient one; and ensuring the optimal electricity consumption by installing inverters on pumps and fans with a power of 7.5 kW or above to respond to changes in equipment loads.

We also intend to facilitate our energy consumption promotion activities further, by seeking advice from energy conservation consultants, energy management companies, and equipment manufacturers, and planning and implementing energy conservation measures based on their advice.

The Morinaga Group is working to introduce renewable energy to contribute to the realization of a decarbonized society.

In FY2023, Takasaki Morinaga Co., Ltd. started receiving solar power through an on-site PPA* in February.

With a generating capacity of 2.0 MW, it is expected to reduce CO2 emissions by more than 1,100 tons per year.

In addition, when the Company moved its head office functions to the Morinaga Shibaura Building, which completed its reconstruction in March 2024, it adopted a plan to supply electricity derived from solar, wind, hydroelectric and other renewable energy sources, to aim essentially zero CO2 emissions.

Furthermore, starting in April 2024, the Tsurumi Site, including the Tsurumi Factory and R&D Center, will also switch to a plan to supply electricity derived from renewable energy sources, which is expected to reduce CO2 emissions by more than 8,500 tons per year.

Rooftop solar panels (Takasaki Morinaga Co., Ltd.) and

new "Morinaga Shibaura Building" (Morinaga & Co., Ltd.)

*On-site PPA: A system in which a power generation company (PPA operator) installs a solar power generation system on the premises of a consumer (company, etc.) at the expense of the power generation company, and owns and maintains the system while supplying electricity generated from the system to the consumer.

As a measure to ensure efficient distribution and environmental friendliness, Morinaga works to improve loading rate using modal shift, joint deliveries with other companies, design product specifications for high loading rates, and introduce demand forecasting using AI for optimal inventory allocation and upgrade supply operations, etc.

As a Specified Consignor* under the revised Act on the Rationalization etc. of Energy Use (“Energy Saving Act”),we calculate and identify the amount of CO2 emitted during transportation.

The General Manager of the Sustainable Management Division of our company attended the meeting of Japan Food Industry Association from the confectionery industry, to discuss various sustainability issues, including environmental issues such as climate change, as well as report to the government and collect information.

At the All Nippon Kashi Association, the General Manager of our company's Procurement Division is the chairperson of the Committee on Environmental Issues. In that Committee, we are involved in making GHG emissions visible and promoting carbon footprints, also examine industry issues and exchanges opinions with the government.