The Morinaga Group believes it is its mission as a food manufacturer to constantly ensure the quality and safety of products and deliver safe and reliable products to customers.

In realizing our Purpose and 2030 Vision, we believe that trust from our customers is the most important. We have established the following quality policy in promoting quality assurance by placing the utmost priority on excellent product quality together with safety and reliability, which are the premise for earning customer trust.

In order to practically implement the quality policy, we have established the Quality Assurance Rules, and are centrally and systematically managing and maintaining the “Quality Assurance Objective (purpose),” “Target Level,” “Manuals Related to Quality Assurance,” and “Quality Standards.” We conduct activities on assuring quality in each department.

All products of the Morinaga brand are developed involving multiple departments and divisions. We implement a cross-sectional “Quality Assessment System” from the product planning phase to eliminate any omissions or oversight in ensuring quality, safety, and legal compliance. In addition, we conduct constant analysis in pursuit of excellent quality. The Analysis Group within the Quality Assurance Division conducts scientific verification and assurance on products and raw materials. Morinaga Institute of Biological Science, Inc. contributes to the verification and assurance of the safety and legal compliance of Morinaga Group's products as well as and legal comploance of products which are produced by the company of Morinaga Group and other company, by developing, manufacturing, and selling food allergy analysis kits. And in preparation of possible quality accidents, we have developed a Crisis Management Response Guidelines that outlines how directors and employees should handle matters in such cases.

In an effort to deliver safe products to our customers, we have established a safety-focused quality assurance system that employs various approaches and mechanisms throughout all processes from product development to procurement, production, distribution, and sales.

If a customer gives feedback about our products after the delivery thereof, we respond to it by conducting a variety of quality investigations and analyses and reporting their results back to the customer. We share these types of information within our organization to leverage it for purposes of product development and improvement If an unexpected event occurs to our products, we would be committed to disclosing information accurately and promptly in order to restore our customers' trust.

While designing the quality and packages/containers and making proper labels, we comply with food-related laws and internal rules set to protect the quality of products on store shelves as well as the quality and safety up to the best-before date.

We have prescribed strict regulations for the raw materials used in our products, and only purchase ingredients from manufacturers who can meet these requirements. We check information on the safety and reliability of raw materials with regard to not only compliance with the Food Sanitation Act but also food additives,allergenic substances and genetically modified organisms (GMOs). We also conduct testing when it is determined to be necessary, confirming that raw materials are safe.

All of our domestic production factories (four Morinaga factories and four affiliated production companies) have obtained the FSSC 22000 certification, an international standard certification for food safety systems or JFS-B standard certification, a Japanse Food Safety Standard.

FSSC 22000 certification:

Mishima Factory, Oyama Factory, Chukyo Factory, Tsurumi Factory, Takasaki Morinaga Co., Ltd., Morinaga Angel Dessert Co., Ltd., Morinaga Dessert Co., Ltd.

JFS-B standard certification:

Osaka Center of Aunt Stella Inc.

Once produced in a factory, products undergo a shipping inspection as a final check in the factory before they reach our customers. The shipping inspection process is the last line of defense to ensure the safety for our customers. Specifically, the process is designed to verify the product's flavor, alignment with specified color tones, dimensions, and weight, and observance of bacterial standards (microorganism control), to identify any broken or defective packages, and to look at whether the best-before date is printed correctly.

Shipping inspection (measuring that dimensions and weight meet product standards)

We set rules and request our business partners in the value chain (such as warehouses and transportation companies) to follow them so as not to impair the quality of our products in order to deliver safe products to our customers.

If a product is reported to be defective by a customer, we immediately carry out an investigation and analysis, verify compliance with quality and regulatory requirements, and report the results to the customer. Further, we quarterly hold a meeting of the Voice of the Customer Review Subcommittee with the aim of taking customers' opinions and feedback into consideration in our company-wide efforts to improve product quality, packaging, labeling, sales campaigns, advertisements, and so forth.

The Morinaga Group is constantly engaged in the analysis and the development of analytical techniques for, nutritional and functional ingredients, chemical substances, heavy metals,microorganisms, and food allergens.Based on scientific and objective evidences, we verify the safety and regulatory compliance of, and provide warranty to, the product development,raw materials, production, logistics, and defective products reported by customers.

Measurement of food allergens (specified raw materials)

As part of our efforts to prevent foreign substances being intentionally inserted into foods, we first of all endeavor to create a workplace environment where it is easy to work and importance is placed on communication, raising employee awareness so that they act in a manner that gives highest priority to customers' safety and peace of mind. On top of this, we implement both tangible and intangible measures to reduce risks, including stricter management of entry/exit to/from factory premises and production facilities, rigid compliance with rules concerning the prevention of contamination (restrictions on personal belongings allowed to be brought in and the handling of chemicals), and installation of camera-based recording systems.

Controller room

Camera-based recording system

Throughout the process from raw materials and ingredients to manufacturing, storage, and delivery, we maintain product traceability by keeping complete records of, and take strict control over, raw materials and products. We also carry out training on a regular basis and confirm whether the traceability system is working properly.

Traceability is checked using with a bar code reader

In addition to being in compliance with laws such as the Food Labeling Act, labeling on packaging provides information important for customers when selecting products. We devise ways to ensure that health-related information such as allergy information, nutritional information, and best-before dates are clearly visible and easy to understand. We also work to raise customer convenience through such efforts as labeling individual packaging with allergen information and cross-contamination statements (a warning for possible contamination arising from production at shared facilities).

And when there are changes in allergen information, it is printed on the package front. Such we are taking steps to accurately communicate information to our customers.

Product label on the package of Morinaga Milk Caramel

Allergen information printed on package front when changes are made

We provide not only legible and easy-to-understand allergen data on product packages but a list of allergens on our website to help customers feel safe when selecting our products. For the sake of customers with allergies, we will continue to carry out strict quality control over specified raw materials and their equivalents as part of our sustained efforts to deliver safe products to our customers.

Allergen-related information (website) Chocoball <Peanuts>

In principle, we do not use genetically modified materials in our products. Soybeans and corn are treated under Identity Preserved Handling (IP Handling) so that genetically modified raw materials are not included.

We use vegetable oils, emulsifiers, flavors, etc. that contain ingredients not critically separated from genetically modified crops. However, it is not required to list these ingredients on product labels, as their protein component has been removed or decomposed during the production process and therefore it is technically infeasible to determine whether the food is genetically modified or not.

We conduct training on quality assurance, including product design and labeling, for newly assigned product development staff. In addition to training new staff, we also work to promote understanding of safe and reliable product design through regular training sessions and lectures by our Quality Assurance Division, Legal Affairs Department, and General Affairs Division through the provision of information on product safety and laws once a month.

We join and participate in various academic societies such as the Japanese Society for Food Hygiene and Safety, various fair trade councils, and various food hygiene related associations including the Japan Food Hygiene Association. Through such activities, we gather the latest information on food quality assurance such as food hygiene and standards and use this knowledge to strengthen our quality assurance system.

For example, we participate in the formulation of the bylaws established by the councils related to fair trade of ice cream, chocolate, and biscuit, and apply and comply with the bylaws. Information on quality and safety is also exchanged during the formulation process. We are working to maintain and improve our quality assurance level by making effective use of these efforts.

Our overseas production sites (Taiwan Morinaga Co., Ltd., Morinaga [Zhejiang] Co., Ltd. and Morinaga America Foods, Inc.) abide by the Morinaga Group Quality Policy, and based on local situation, have acquired international food safety management system certifications FSSC 22000 (in Taiwan and Zhejiang) and SQF Codes Edition 9* (in the United States), ensuring they manufacture safe products.

Process inspection in Morinaga America Foods, Inc.

X-ray inspection in Morinaga America Foods, Inc.

In addition to its own production factories, the Morinaga Group has many manufacturing partners in Japan contracted to carry out its production.

When contracting manufacturing partners for production, we confirm in advance that those partners have in place a quality control system that is comparable to that of the Morinaga Group's production factories. Confirmation is made through GMF Inspection,* whose checklist consists of 150 or more items.

Once contracted, GMF Inspections are conducted regularly and the manufacturing partners are requested to maintain and enhance their quality control systems. To facilitate the efforts of manufacturing partners, the Morinaga Group shares information with them and provides support (information exchange forums, quality improvement support, etc.).

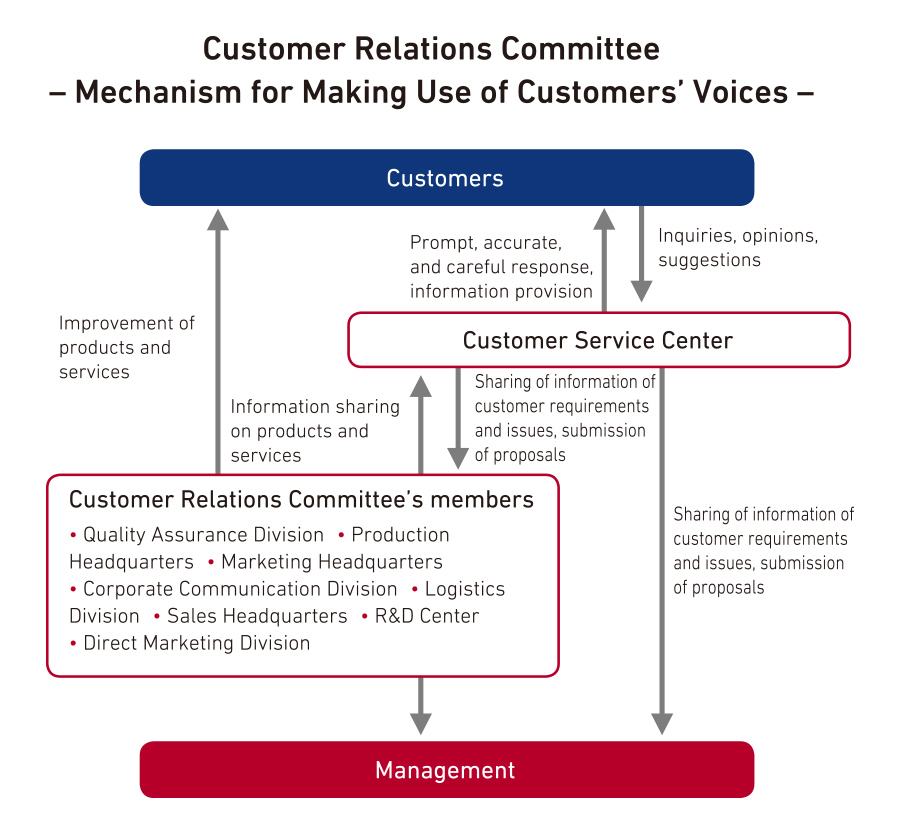

Led by the Customer Service Center, Production Headquarters, and Quality Assurance Division, a meeting of the Voice of the Customer Review Subcommittee is held quarterly to share customers' voices among all relevant divisions. We take customers' voices seriously and use them to help improve customer satisfaction. In addition, we agree with consumer-oriented management recommended by the Consumer Affairs Agency and have made a voluntary declaration on consumer-orientation.

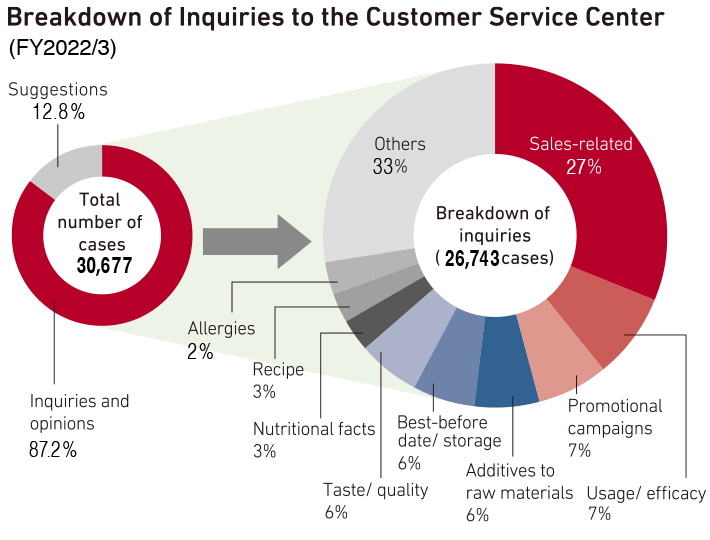

Our Customer Service Center constantly implements improvements aimed at achieving a higher level of customer satisfaction in accordance with ISO 10002, with which the Company made a self-declaration of conformity in 2013. We receive and respond to opinions and requests from customers via a number of channels, including a toll-free number, e-mail, and letters, and are mindful of providing sincere, prompt, and accurate responses. All of the customers' voices we received are shared with the entire company through daily and monthly reports, which enables us to detect issues at their early stages, and incorporate these voices in product and service improvement. Moreover, we have published Q&A on our website to help our customers find solutions speedily.

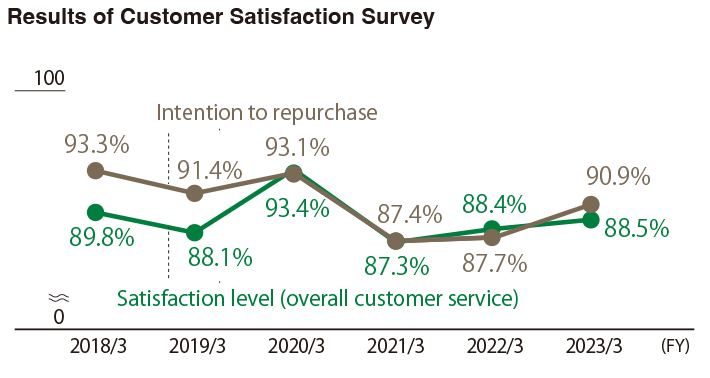

The Customer Service Center analyzes every piece of every suggestion, investigates the cause, and reports the result to the customer who gave the suggestions. With the report, we enclose a postcard that requests the recipient to respond to a survey, and the results of which are regularly analyzed and examined for details on overall satisfaction and repurchase intentions. We will apply the results of the survey to improve our services and continue to strive to increase customer satisfaction by being even more considerate of our customers.

We share our customers' voices across the organization and make use of them to detect issues in an early stage and create better products and services. Favorable comments about our products are published in wall newspapers, which are distributed monthly to individual divisions and departments as well as branches and factories nationwide. Even when we receive critical comments, we take them seriously and make use them to improve our products and services. Some of the improvements made in response to them are posted on our website.

Use of easier-to-open caps (website)

Wall newspaper No. 130, published in May 2021

We regularly update the list of questions and answers on our website to improve the content. Most frequently asked questions are included in the FAQ section. Questions in the section are sorted in the order of how frequently they are asked, helping users find necessary information easily.

We provide training on compliance and labeling related to advertising and marketing for newly assigned product development staff with the aim of offering advertising and marketing in a manner that is responsible to society. In addition, when launching products, we have a mechanism in place for multiple departments to check for inappropriate expressions such as compliance violations so that all related parties can work together to deliver safe and reliable products to our customers.